Instruction and description

1) Operating principle

1.1)finalize the design:

Use PVC/PE through clamp structure and pass into molding district to preheat mould ——>making shape mould ——>air filling mould——>membrane making shape. Triangle knife side cut,dotted line cutting.

1.2)filling part:

There are 3-6 filling terminal,with embedded type filling for shaped suppository for one time, filling accuracy can get ±1%,there is electrical heating system to keep heat for raw material barrel, and there is mixing motor for raw material, the raw material of charging basket entrance into filling terminal through circulator, and the rest raw material circulate to the barrel for next filling.

1.3) cooling part

Whole row is finished filling and passed into cooling shelf, cooling box is set cooling water unit, and cooling air is transformed by four condensers which is into the cooler bin to cool suppository.

1.4)seal and print code part:

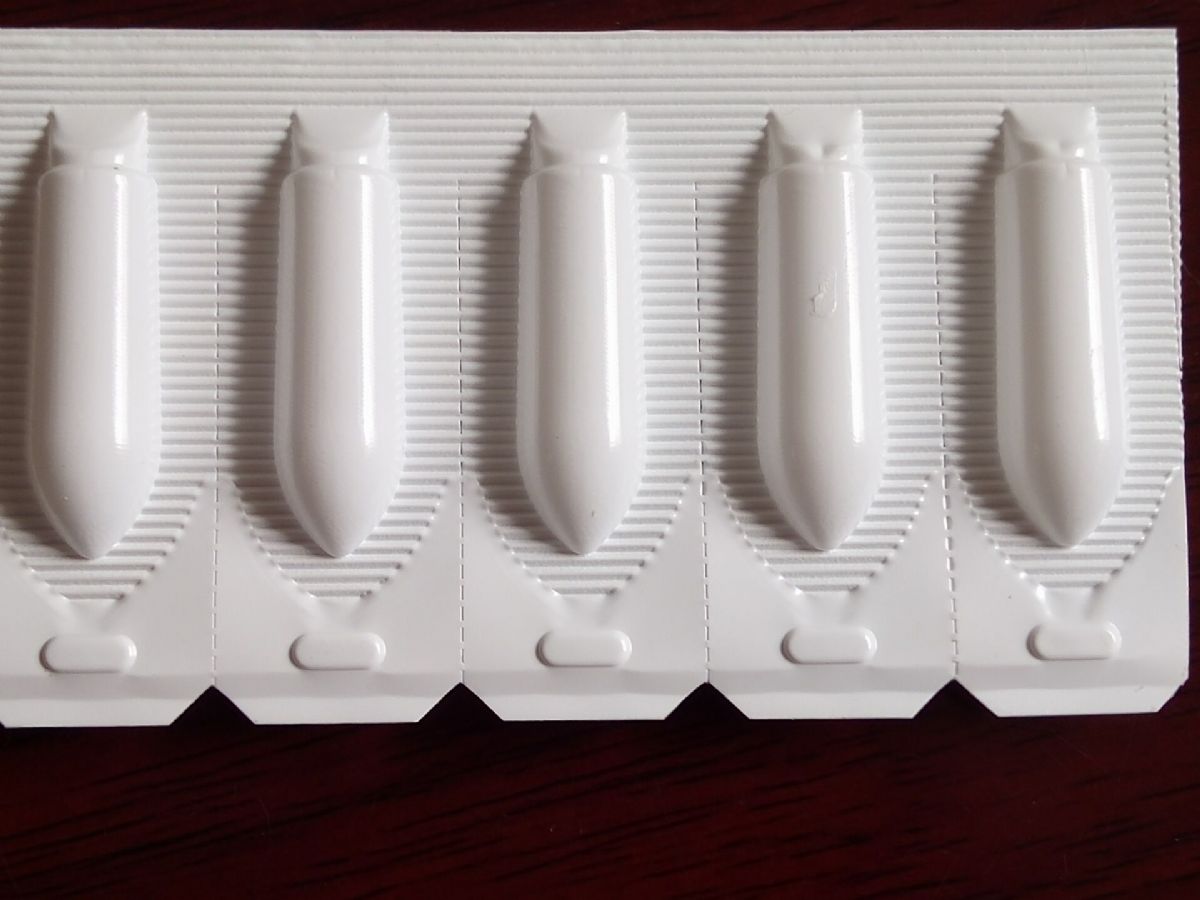

Cooled solid suppository is sent to the seal district: preheat mould——>seal mould——>code print mould. And finished product is cut for 5 grains or 6 grains for a group.(according to customer’s requirement)

WECHAT PUBLIC NUMBER

WECHAT PUBLIC NUMBER

Hotline:0938-2721678 Landline:0938-2799882 fax:0938-2721778

E-mail:info@hykj.com

address:No.2,Huayuan Avenue,Shetang Economic Development Area,Maiji District,Tianshui City,Gansu,China

Copyright 2007-2026 © Tianshui Hua Yuan Shang Yu Technology Co., Ltd

All rights reserved.